|

M/RAD can develop equipment that is customized for your individual needs. Here are some examples of custom equipment that we have supplied customers in the past.

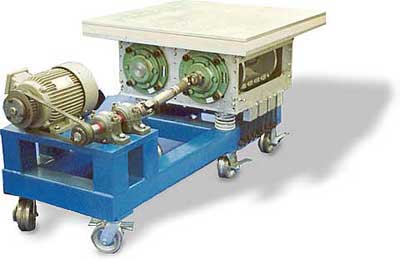

Custom F211

The task was to provide a high acceleration and high displacement machine. Since the weight of the motor significantly influences the output of the machine and since part of the shaker limitation is due to the amount of vibration the motor can endure, M/RAD built a machine where the motor is detached. In this way, the machine no longer carries the weight of the motor and can meet g levels of up to 20, nor is the machine bound by the motor’s vibration limitations.

Custom ESS Tool

The task was to provide a horizontal, linear sweep with constant displacement for mainframes of various sizes and configurations. The photo on the right shows the front of the machine where the controls are located. The photo on the left shows the back of the machine where an attachment bar may be situated at various heights depending on the height requirement of the unit under test. Note that inside the enclosure, there is packaged a standard 311 mechanism rotated 90 degrees to generate the horizontal motion. Note that the system is provided on Casters for portability.

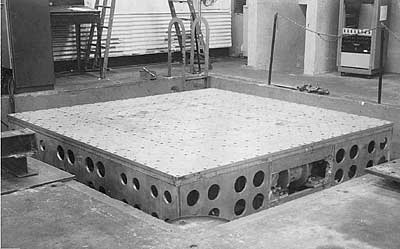

Custom F211-167

The task was to provide a large force, large table mechanical shaker to be located in a pit to satisfy MIL-STD-167-1 with payloads up to 10,000 lbs.

|

|